![]() Following the successful introduction of our SYNERGi Premier cells we have now launched our new SYNERGi Classic for Doosan lathes and Doosan machining centres.

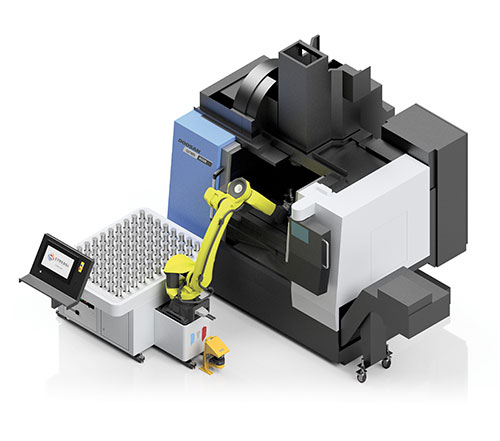

Following the successful introduction of our SYNERGi Premier cells we have now launched our new SYNERGi Classic for Doosan lathes and Doosan machining centres.

SYNERGi Classic cells are smaller than SYNERGi Premier cells and are ideal for the automated manufacture of smaller parts.

Instead of featuring a 5 Drawer loading/unloading station, SYNERGi Classic cells have a loading pattern (tray) which is 1400mm x 1000mm in size.

The pattern system uses grid plates for exact part location, and typical part sizes for the SYNERGi Classic range from 20mm to 400mm.

These automated cells are powered by our own proprietary (SYNERGi) software and, at the heart of every system, is a sophisticated and intuitive HMI that incorporates a wide-range quality control, monitoring and inspection features and capabilities.

SYNERGi Classic

SYNERGi Classic systems feature a 6-axis industrial robot, a loading/unloading system, a 17” touchscreen HMI, locating plates, pneumatic 2- or 3- jaw grippers, integrated SICK safety systems and industrial fencing.

SYNERGi Classic configurations

SYNERGi Classic: (Milling)

SYNERGi Classic : (Turning)